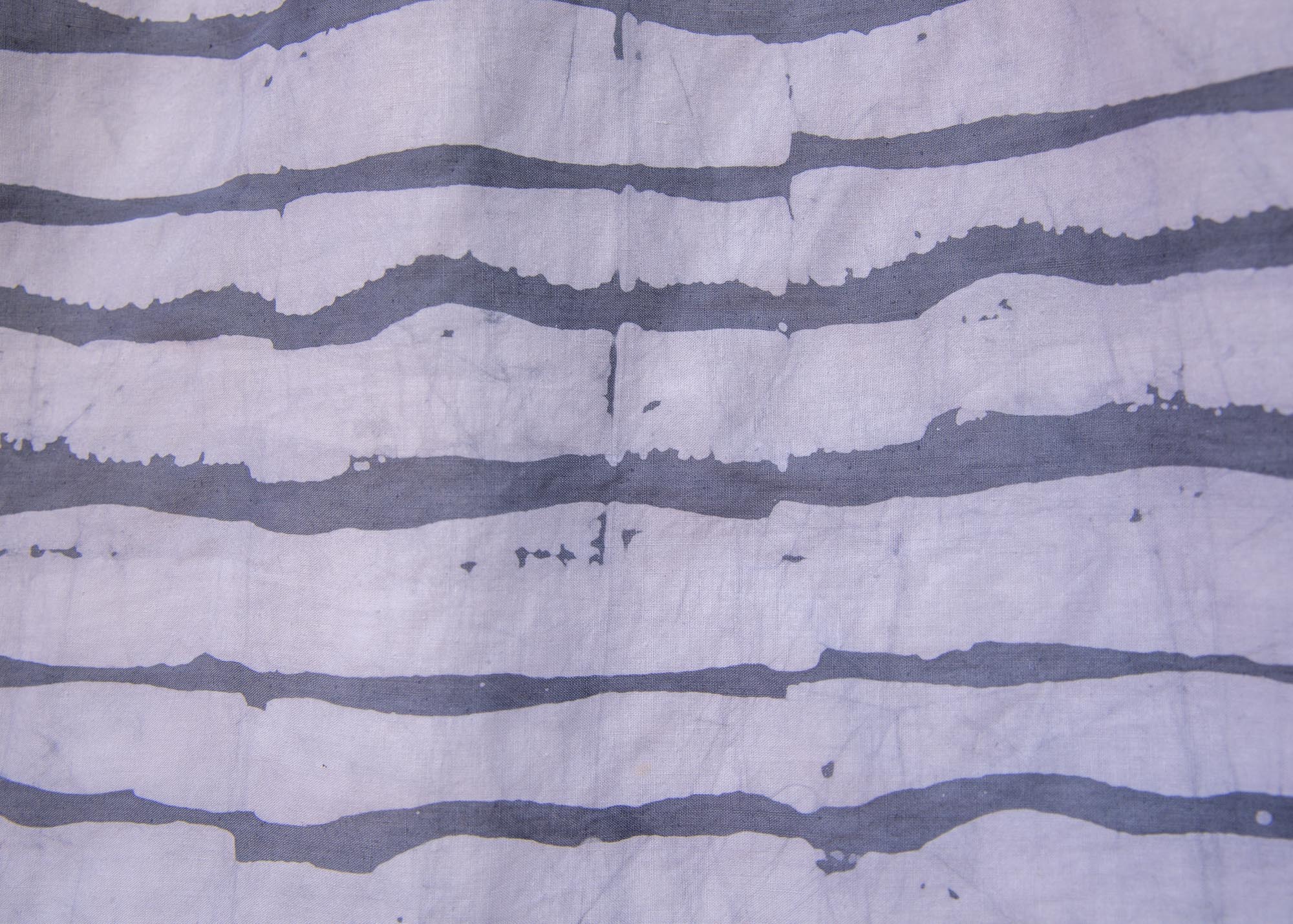

Handprinted in Ghana

We met Edwina and her collective of batik dyers four years ago in Accra, and from the moment we saw their work, we made it a priority to produce fabrics with this group. As a small business, we experience first-hand the importance of commitment and reliability when working with all levels of our supply chain, and it's paramount that we uphold the same commitments to those who depend on us! Four years later, we've produced over 40 unique textiles together, totaling over 38,000 meters, each hand-printed on cotton sourced in Ghana.

If you're unfamiliar with the batik process, here's how it works! First, recycled wax is melted and applied to the fabric using a cut out pattern. (Edwina and her team use foam to create their stamps, since they're easy to cut and repurpose, as opposed to wooden stamps.) The printed fabrics then go into a dye bath where they can stay anywhere from a few hours to a day! After soaking, the fabric is transferred to another bath where it's heated, to remove the wax. For designs with multiple colors, the fabric is dyed, heated, then dried outside, then printed and dyed again!

We started working with Edwina in late 2018 because we loved the idea of developing hand-dyed textiles for our clothing. We were excited by the idea of bringing the story of wax prints full circle, from the rotary printed textiles that we were sourcing in the markets in Kenya and Tanzania to creating hand printed batiks, where the wax print textile tradition began. We're so proud to be able to continue to support this traditional textile production process and work with this wonderful team!